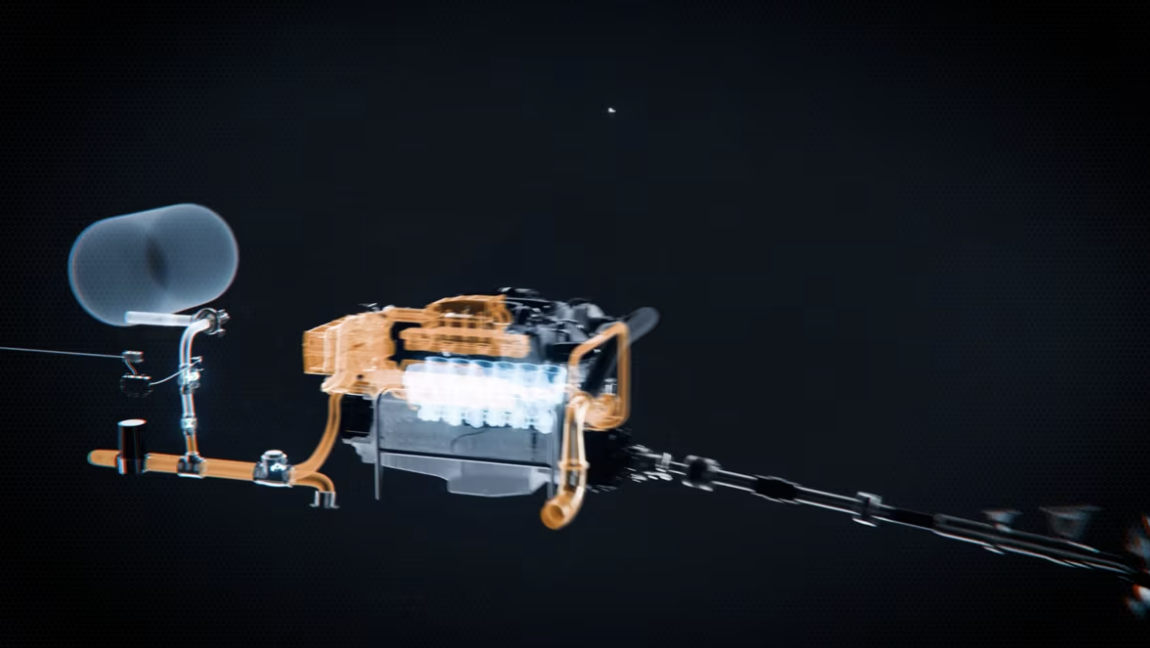

Inboard propulsion engines have an entirely unique set of considerations that prevent easy or routine flushing. Wet/dry exhaust system configurations, oil/fuel coolers, turbos, raw water intakes, raw water flow rates, thermostat locations, strainers, impeller pump locations, and other challenges make freshwater flushing nearly impossible to execute on a regular basis. As such, freshwater flushing of inboard engines it usually relegated to seasonal or chemical flushes.

PHIBER is the ONLY automated freshwater flush (FWF) solution designed for ALL inboard marine propulsion engines that use seawater in their raw water networks. PHIBER’s patent-pending FWF Manifold and Control Module operate in concert to ensure safe and optimally-effective flushing for your inboard engine, at the touch of a button.

If performed at the end of every run cycle when the engine is still close to operating temperature, most inboard engines do NOT require significant amounts of water to accomplish a proper FWF. As the flush begins, the seawater in the raw water network immediately begins to dilute, and once the seawater has been purged, the FWF is complete.

The duration and total amount of fresh water needed for a proper FWF of inboard engines are only and directly related to the following:

The PHIBER System will “pickle” the engine’s raw water circuit with freshwater, preventing the buildup of corrosion and bio/mineral-scale in critical areas, which can cause overheating problems if left unchecked.

PHIBER Systems ensure miserly water usage when executing a freshwater flush, which is critical for smaller vessels with limited freshwater tankage or if dock water is expensive in your marina, or if you’re just concerned about protecting our local water resources.

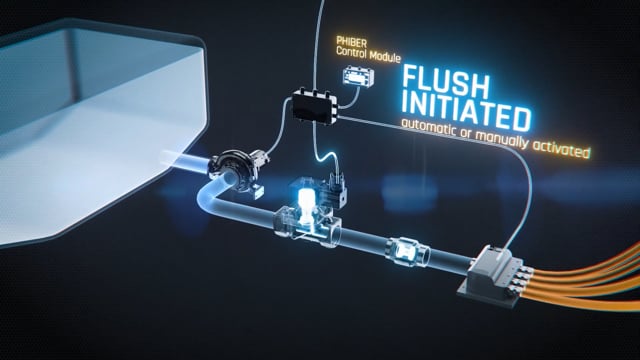

See the step-by-step process in action in this animation.

A correctly sized PHIBER FWF Manifold Kit and Control Module provides the core components necessary for executing proper FWF on an inboard engine. Raw water flow rates will vary depending on the raw water plumbing sizes, so achieving proper flow rates from the freshwater source will be critical. In many cases, the vessel’s native freshwater pump can provide adequate GPM flow, however, for larger or high-performance engines, the addition of a dedicated FWF Feed Pump may be necessary.

The full installation will include commonly available hoses, fittings, and clamps which are available at local marine chandleries.

Professional installation is always recommended. Contact us for more details.

Freshwater flushing (FWF) of outboard engines is a standard burden of ownership. Every OEM of outboard engines provides recommendations in their service/owner manuals for FWF procedures after every use, and for an average duration of 5-10 minutes… but at the end of the day, it’s the last thing anyone truly wants to do.

The total time for setup, flushing and breakdown is typically 15 minutes… for one engine. If flushing two engines, three engines, or maybe even four, you’re investing significant time and effort!

The reality of any OEM’s FWF recommendation is this:

OEMs of outboard engines have no way of knowing the conditions under which the actual flush will be performed, so recommendations are “universal” in that they must allow for unknown conditions… including cold engines, potential blockage or existing scale buildup within raw water cooling networks, and unknown freshwater flow rates.

PHIBER’s patent-pending FWF Manifold and Control Module operate in concert to ensure safe and optimally-effective flushing for your outboard engine(s), automatically, or at the touch of a button.

The duration and total amount of fresh water needed for a proper FWF of outboard engines are only and directly related to the following:

If performed at the end of every run cycle when the engine is still close to operating temperature (and the thermostat is still open), most outboard engines do NOT require significant amounts of water to accomplish a proper FWF. As the flush begins, the seawater in the raw water network immediately begins to dilute, and once the seawater has been purged, the FWF is complete.

This results in miserly water usage when executing a freshwater flush, which is critical for smaller vessels with limited freshwater tankage or if dock water is expensive in your marina, or if you’re just concerned about protecting our local water resources.

For the discriminating boat owner, a PHIBER System offers a custom-tailored solution that addresses unique challenges often found on yachts… finding a balance between aesthetics and function. Its design allows for custom configuration that can operate surreptitiously, with no discernible footprint on deck, or in concert with existing systems when warranted. PHIBER Systems are fully adaptable to meet any installation challenge.

The PHIBER System can be scaled and adapted to support any engine configuration. Consult with your installer about “the art of the possible” for your particular engine setup.

PHIBER Systems allow for creative solutions in designing a freshwater flush system aboard your boat.

Freshwater Flushing can be executed simultaneously across multiple engines, or sequentially through the use of a multi-valve control.

Connection to most modern outboard engines can be made using existing flushing ports and plumbing networks, as most OEMs provide a freshwater flushing connection that is pre-plumbed from the external engine cowling to a dedicated flushing inlet at the engine block.

If there is not a pre-configured flushing port on the engine, or if the existing flushing configuration is not easy to work with, it is possible to connect to the engine’s cooling circuit under the cowling in several different ways that seamlessly blend into the engine’s existing rigging.

For exotic and high performance outboard engines, PHIBER can be configured to support unique flushing configurations using non-traditional methods and materials.

Professional installation is always recommended. Contact us for more details.

Generators are similar to inboard propulsion engines because they can have an entirely unique set of considerations that prevent easy or routine flushing. Wet/dry exhaust system configurations, oil/fuel coolers, raw water intakes, raw water flow rates, thermostat locations, strainers, impeller pump locations, and other challenges make freshwater flushing nearly impossible to execute on a regular basis. As such, freshwater flushing of inboard engines it usually relegated to seasonal or chemical flushes.

PHIBER is the ONLY automated freshwater flush (FWF) solution designed for ALL inboard marine generator engines that use seawater in their raw water networks. PHIBER’s patent-pending FWF Manifold and Control Module operate in concert to ensure safe and optimally-effective flushing for your generator engine, automatically, or at the touch of a button.

If performed at the end of every run cycle when the engine is still close to operating temperature, most inboard engines do NOT require significant amounts of water to accomplish a proper FWF. As the flush begins, the seawater in the raw water network immediately begins to dilute, and once the seawater has been purged, the FWF is complete.

The duration and total amount of fresh water needed for a proper FWF of inboard engines are only and directly related to the following:

The PHIBER System will “pickle” the engine’s raw water circuit with freshwater, preventing the buildup of corrosion and bio/mineral-scale in critical areas, which can cause overheating problems if left unchecked.

PHIBER Systems ensure miserly water usage when executing a freshwater flush, which is critical for smaller vessels with limited freshwater tankage or if dock water is expensive in your marina, or if you’re just concerned about protecting our local water resources.

See the process step-by-step in this animation.

A correctly sized PHIBER FWF Manifold Kit and Control Module provides the core components necessary for executing proper FWF on a generator engine. Raw water flow rates will vary depending on the raw water plumbing sizes, so achieving proper flow rates from the freshwater source will be critical. In many cases, the vessel’s native freshwater pump can provide adequate GPM flow, however, for larger or high-performance engines, the addition of a dedicated FWF Feed Pump may be necessary.

The full installation will include commonly available hoses, fittings, and clamps which are available at local marine chandleries.

Professional installation is always recommended. Contact us for more details.

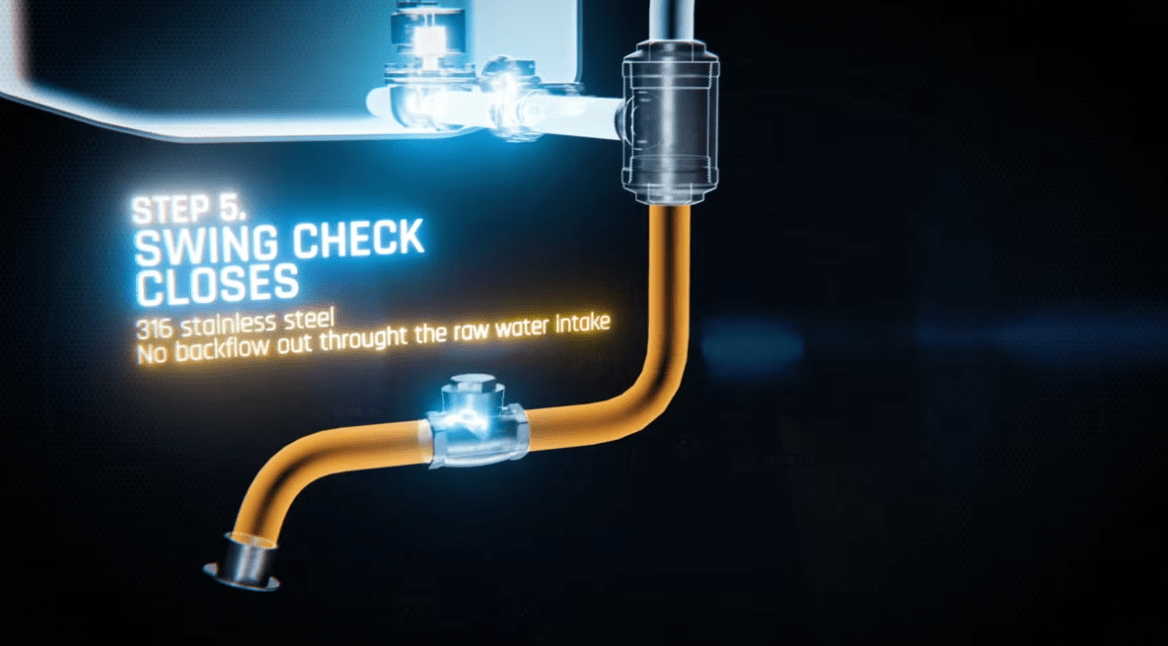

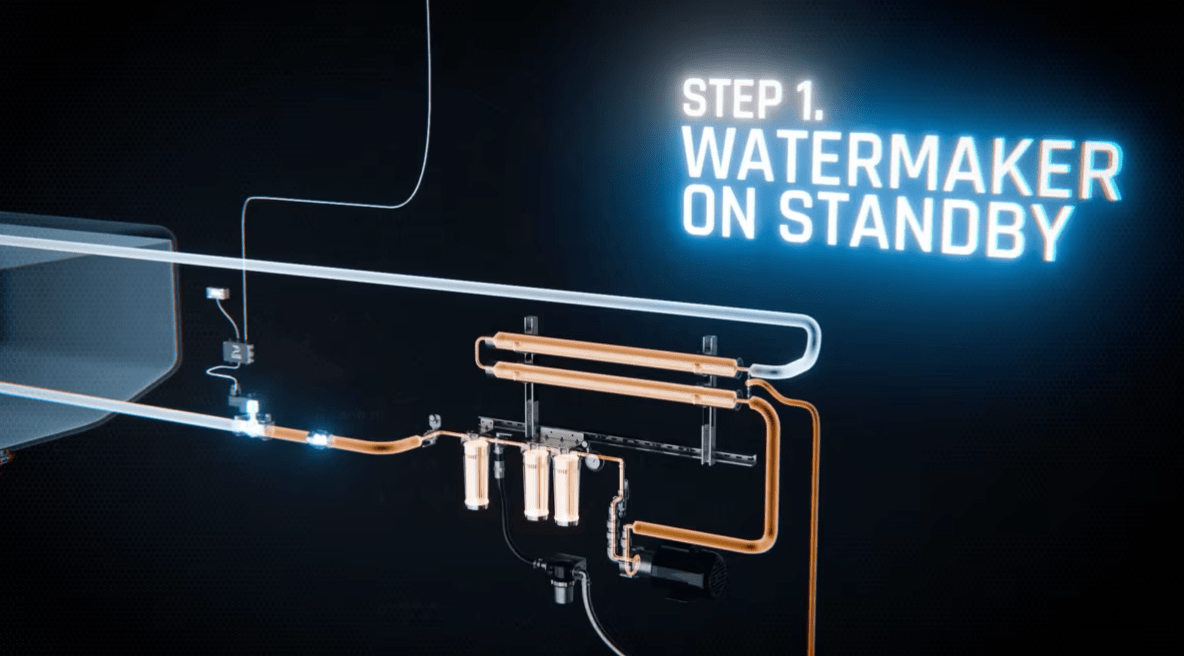

Watermakers are critical gear for vessels that spend a lot of time at sea, and protecting their membranes by routine freshwater flushing ensures that they are always ready to serve.

Installing a PHIBER solution to handle the freshwater flushing is fairly straightforward. Once installed, it provides a proper FWF for your watermaker, automatically at the end of each run cycle, manually at the touch of a button, or on a schedule to preserve the membrane during periods of inactivity.

The patent-pending FWF Manifold and Control Module operate in concert to ensure safe and optimally-effective flushing.

Unlike engine applications, both the INBOARD and OVERBOARD Manifolds are compatible with watermakers. Selection of a FWF Manifold simply depends on the configuration of the watermaker installation. If the intent is to flush the complete raw water intake network, then the INBOARD Manifold should be used. If only the watermaker itself is to be flushed, then the OVERBOARD Manifold is sufficient.

Membranes and their networks do NOT require significant amounts of water to accomplish a proper FWF. As the flush begins, the seawater in the raw water network immediately begins to dilute, and once the seawater has been purged, the FWF is complete.

See the process step-by-step in this animation.

The PHIBER FWF Manifold Kit and Control Module provides the core components necessary for executing proper FWF on a Watermaker. In many cases, the vessel’s native freshwater pump can provide adequate GPM flow, however, for larger or high-capacity watermakers, the addition of a dedicated FWF Feed Pump may be necessary.

The full installation will include commonly available hoses, fittings, and clamps which are available at local marine chandleries.

Professional installation is always recommended. Contact us for more details.

Vessel Gyroscopic Stabilization Systems typically have a raw-water cooling circuit that is similar to those found on inboards engines (they may include intake strainers, thermostats, raw water pumps, and an overboard discharge). They do not, however, have the other challenges related to inboard engines, so installing a PHIBER solution is fairly straightforward.

Unlike engine applications, both the INBOARD and OVERBOARD Manifolds are compatible. It is recommended that the INBOARD Manifold be selected if the vessel remains in the water between operation cycles, and the OVERBOARD Manifold be installed if the vessel is out of the water (i.e. on a lift, or a trailer) between operation cycles.

PHIBER’s patent-pending FWF Manifold and Control Module operate in concert to ensure safe and optimally-effective flushing for your Gyro Stabilizer, automatically, or at the touch of a button.

If performed at the end of every run cycle when the Gyro is still close to operating temperature, most Gyro cooling systems do NOT require significant amounts of water to accomplish a proper FWF. As the flush begins, the seawater in the raw water network immediately begins to dilute, and once the seawater has been purged, the FWF is complete.

The duration and total amount of fresh water needed for a proper FWF is only and directly related to the following:

If performed at the end of every run cycle, only the exact amount of fresh water to fully displace the seawater is necessary.

This results in miserly water usage when executing a freshwater flush, which is critical for smaller vessels with limited freshwater tankage, if dock water is expensive in your marina, or if you’re just concerned about protecting our resources.

See the step-by-step process in action in this animation.

The PHIBER FWF Manifold Kit and Control Module provides the core components necessary for executing proper FWF on a Gyroscopic Stabilization System. Raw water flow rates will vary depending on the system, so achieving proper flow rates from the freshwater source will be critical. In many cases, the vessel’s native freshwater pump can provide adequate GPM flow, however, for larger or high-performance Gyros, the addition of a dedicated FWF Feed Pump may be necessary.

The full installation will include commonly available hoses, fittings, and clamps which are available at local marine chandleries.

Professional installation is always recommended. Contact us for more details.

This section of the website is under construction

Stay connected and receive PHIBER news and updates.

PHIBER Systems, Inc. © All rights reserved