The PHIBER System supports a wide range of applications, from simple to complex. Depending on the totality of raw water network(s) in a particular vessel, installations may include only a single PHIBER System, or multiple. The PHIBER System is fully configurable for unique needs, and flexible installation methods allow for maximum benefit and minimal space requirements.

For optimum performance and effectiveness, individual raw water networks (defined by a dedicated “intake” and “exit” for sea water) should have a singular assigned PHIBER System (FWF Manifold and Control).

For example, if a vessel has a diesel propulsion engine and a diesel generator engine, each with wet exhaust, then each engine will be best maintained by having an individual PHIBER System for their respective raw water networks. Each module will be individually configured and/or manually operated based on the specific requirements of the raw water circuit.

FWF Manifolds can be plumbed into one singular unit that operate using a singular FWF pump, minimizing complexities.

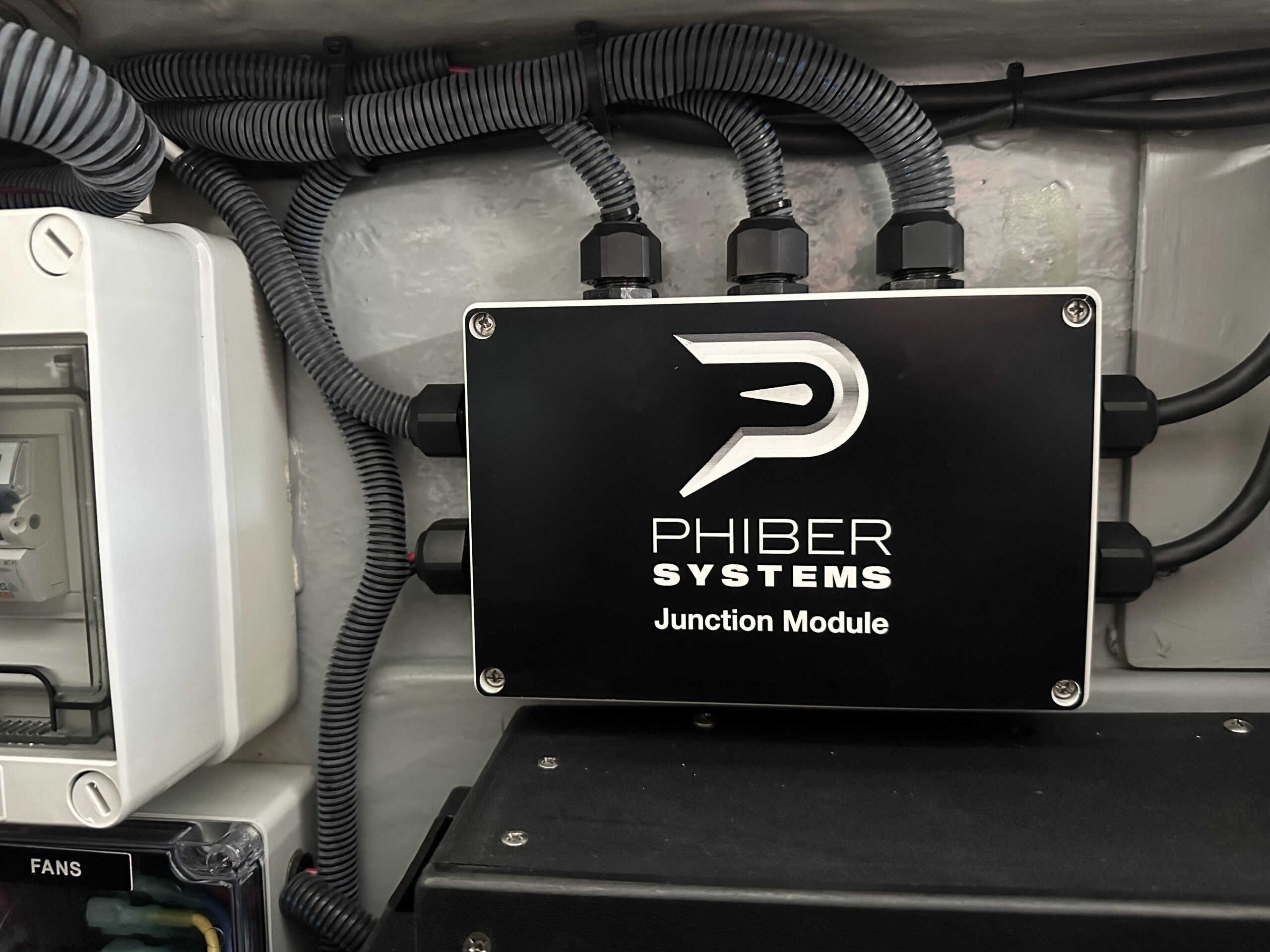

Junction Modules to streamline the installation of the various circuits, and are provided in accordance with the requirements from the installer, and allow “single” or “multi” system configuring.

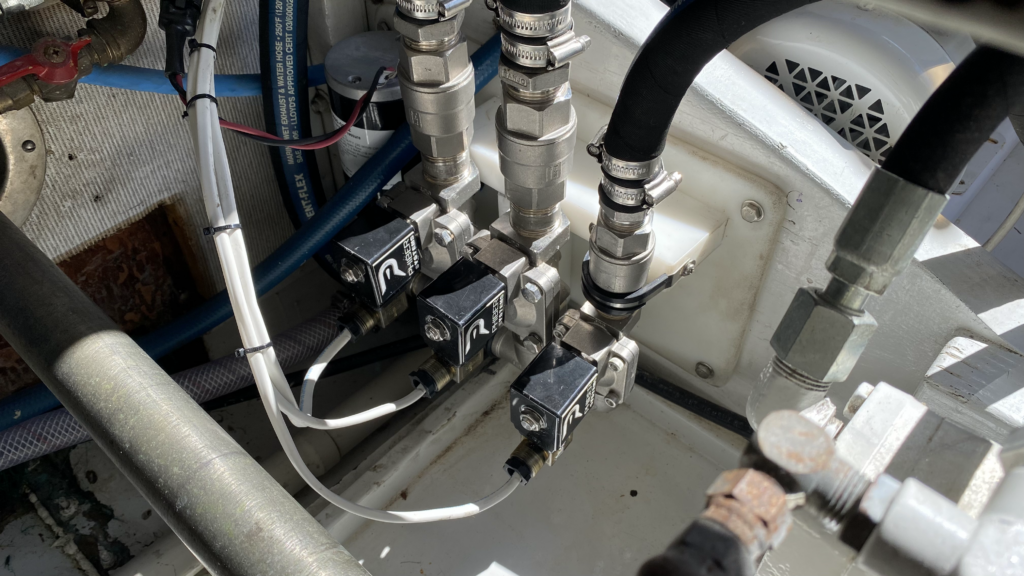

PHIBER FWF Manifolds are custom configured during each installation to be as unique as the system that it serves. The strategic placement and orientation of the components within the plumbing network are the only critical steps in creating a custom PHIBER FWF Manifold that complements a vessel’s raw water networks.

Building a custom manifold for a twin-outboard engine system

For multi-engine outboard configurations, the use of an aftermarket flushing valve sequencer such as a Reverso, SeaMule, or Superflush can streamline a PHIBER installation. These systems should be installed downstream from the PHIBER Manifold. More information on flushing with existing systems can be found in the PHIBER Compatibility section.